Racking Labels

Keep your warehouse running smoothly with our high-quality rack labels. Our labels are easy to install and customisable, allowing you to track your inventory and optimise your storage space. These labels are designed to withstand the wear and tear of daily warehouse operations, ensuring that they will last for years to come.

Efficiency at Your Fingertips

Say goodbye to the chaos of the warehouse with our top-of-the-line racking labels! Our labels are designed to make your warehouse operations more efficient and organised. With our aisle markers, bay markers, letter and number tiles, label holders, location markers and ticket pouches, you can easily identify and locate products in your warehouse. With different mounting options like self-adhesive, magnetic, or clips, you have the flexibility to choose the perfect solution for your warehouse needs. Save time and reduce errors with our top-notch racking labels.

What Are Racking Labels?

Racking labels are identification markers used in warehouses to mark aisles, bays, shelves, and other storage areas. They are used to organise and locate products within a warehouse, making it easier and faster to find and pick orders. Racking labels typically include aisle markers, bay markers, letter and number tiles, label holders, location markers, and ticket pouches. They can be mounted on the racking or shelving using different methods like self-adhesive, magnetic, or clips. The purpose of racking labels is to increase efficiency and reduce errors in warehouse operations.

What Are Some Common Uses for Racking Labels?

Racking labels are used to identify and locate products within a warehouse. Some common uses for racking labels include:

- Identifying aisles and bays: Racking labels can be used to mark aisles and bays, making it easy to navigate the warehouse and locate products.

- Labelling shelves: Racking labels can be used to label shelves and storage areas, making it easy to find specific products.

- Organising inventory: Racking labels can be used to organise inventory by product category or location.

- Assisting with order picking: Racking labels can be used to assist with order picking by providing clear identification of products and their location.

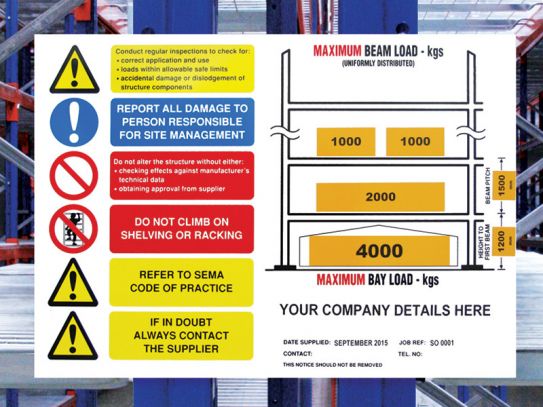

- Enhancing safety: Racking labels can be used to enhance safety by clearly identifying hazardous materials or areas that require special precautions.

- Improving warehouse efficiency: Racking labels can be used to improve warehouse efficiency by making it easier to find products, reducing the need for manual inventory counts, and decreasing the number of errors.

What Are the Different Types of Racking Labels?

There are several different types of racking labels that can be used in a warehouse, including:

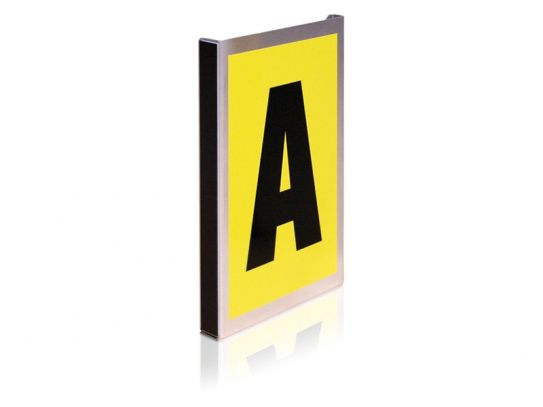

- Aisle markers: These labels are used to mark aisles and help warehouse workers navigate the facility.

- Bay markers: These labels are used to mark bays, or specific areas within an aisle, and help warehouse workers locate products.

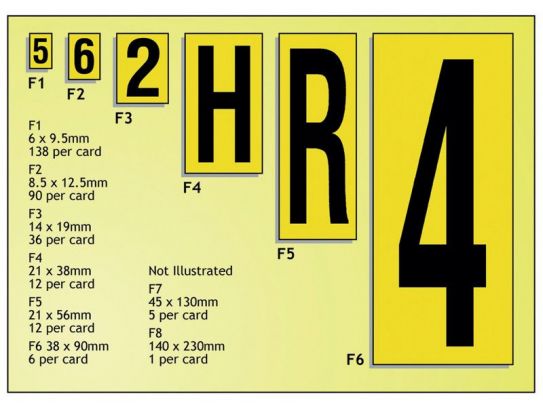

- Letter and number tiles: These labels are used to create custom labels for shelves and storage areas. They can be used to identify specific products or to organise inventory by product category or location.

- Label holders: These labels holders are used to hold and display a variety of labels, including barcode labels, product labels, and location labels.

- Location markers: These markers are used to indicate the location of specific products or materials within the warehouse.

- Ticket pouches: These pouches are used to hold and display tickets or labels that provide additional information about products, such as product details, handling instructions, or expiration dates.

All of these types of labels are available with different mounting options, like self-adhesive, magnetic, or clips.

What Are the Key Features to Consider When Choosing Racking Labels?

When choosing racking labels, there are several key features to consider to ensure they meet the specific needs of your warehouse:

- Durability: Racking labels need to be able to withstand the harsh conditions of a warehouse environment, such as exposure to dust, moisture, and extreme temperatures.

- Visibility: Racking labels need to be highly visible and easy to read in order to be effective. They should be large enough to be easily seen and read from a distance.

- Flexibility: Racking labels should be versatile and flexible enough to be used in a variety of warehouse settings, from small storage areas to large, high-bay warehouses.

- Ease of Use: Racking labels should be easy to install and remove, which can save time and money. Some labels come with mounting hardware, such as clips or magnetic backings, that make installation quick and easy.

- Customisability: Some racking labels are customisable, which allows you to add your own text or graphics to the labels. This can be useful for adding product information or company branding to the labels.

- Compatibility: Some racking labels are designed to work with specific types of racking or shelving systems, so it is important to ensure that the labels you choose are compatible with your existing warehouse infrastructure.

- Material: Racking labels are available in a variety of materials, such as paper, plastic, and metal. Selecting the right material depends on the usage, budget, and durability needed.

What Is the Best Way to Mount Racking Labels?

The best way to mount racking labels depends on the specific needs of your warehouse and the type of labels you are using. Here are a few common options for mounting racking labels:

- Self-adhesive: Self-adhesive labels can be easily applied to any smooth, clean surface, making them a popular choice for many warehouses. They can be easily removed without leaving residue.

- Magnetic: Magnetic labels can be attached to metal surfaces using a magnetic backing, making them a good option for warehouses with metal racking or shelving.

- Clips: Clips can be used to attach labels to wire shelving or other types of racking. They are easy to install and remove, and won't damage the racking.

- Screws: Screws can be used to attach labels to wooden or other types of racking, this is a more permanent option and it works well for heavy-duty usage.

- Ties: Ties can be used to attach labels to pipes or other cylindrical surfaces. These are great for labelling items that are not able to be labelled with adhesive or other methods.

Ultimately, the best way to mount racking labels depends on the specific needs of your warehouse, the type of racking or shelving you are using, and the type of labels you have chosen. It's important to consider the ease of use, durability, and flexibility of the mounting method when making your decision.

What Is the Best Material for Racking Labels?

The best material for racking labels depends on the specific needs of your warehouse and the type of labels you are using. Here are a few common materials used for racking labels:

- Paper: Paper labels are a cost-effective option and can be easily printed on with a standard printer. They are not as durable as other options, but they are lightweight and easy to install.

- Plastic: Plastic labels are more durable than paper labels, and can withstand exposure to moisture and dust. They can be printed on with a standard printer or laser printer, and are available in a variety of colours.

- Metal: Metal labels are highly durable and can withstand exposure to harsh conditions such as heat and chemicals. They can be engraved or printed on, and are resistant to fading. They are more expensive than paper or plastic options.

- Vinyl: Vinyl labels are durable, flexible and resistant to sunlight and weathering. They are available in a variety of colours, and can be printed on with a standard printer or cut out with a vinyl cutter.

Ultimately, the best material for racking labels depends on the specific needs of your warehouse, the type of racking or shelving you are using, and the expected lifespan of the labels. It's important to consider the durability, flexibility, and cost of the material when making your decision.

What Safety Considerations Should Be Taken Into Account When Using Racking Labels?

When using racking labels, there are several safety considerations that should be taken into account to ensure the safety of warehouse workers:

- Visibility: Racking labels should be highly visible and easy to read to help warehouse workers quickly and easily locate products and identify hazards.

- Readability: Racking labels should be easy to read, with clear and legible text and graphics. This will reduce the risk of errors and accidents caused by confusion or miscommunication.

- Hazard identification: Racking labels should be used to clearly identify hazardous materials or areas that require special precautions, such as hazardous material storage areas, fire exits, and emergency equipment locations.

- Material safety: Racking labels should be made of materials that are non-toxic and safe to handle. They should not contain any hazardous substances that could pose a risk to warehouse workers.

- Durability: Racking labels should be durable enough to withstand the harsh conditions of a warehouse environment, such as exposure to dust, moisture, and extreme temperatures.

- Installation: Racking labels should be installed in a way that is easy to read and understand, and that does not pose a risk of injury to warehouse workers.

- Maintenance: Racking labels should be maintained and kept clean to ensure they remain legible and easy to read.

- Compliance: Racking labels should be compliant with relevant regulations and industry standards, such as OSHA, GHS, and ANSI.

By taking these safety considerations into account, you can help ensure the safety of warehouse workers and reduce the risk of accidents and errors in your warehouse.

Are There Any UK or European Industry Standards or Regulations That Apply to Racking Labels?

Yes, there are industry standards and regulations in the UK and Europe that apply to racking labels.

- In the UK, the Health and Safety Executive (HSE) has issued guidance on the safe use of racking and shelving in warehouses, which includes recommendations for labelling and signage. The guidance states that racking labels should be used to clearly identify the location of products, and that labels and signage should be legible, clearly visible, and easy to understand.

- In Europe, the European Union has issued regulations for the classification, labelling, and packaging of chemicals, which includes guidelines for labelling of hazardous materials. These regulations are known as CLP (Classification, Labelling, and Packaging) Regulation. This includes the use of pictograms and hazard statements on the labels of hazardous materials to ensure workers can easily identify the hazards.

Additionally, the European standard EN 15635:2008, provides guidelines for the safe use of industrial storage equipment, including racking and shelving. This standard includes provisions for labelling, signage and marking of storage equipment, and it is to be used in conjunction with the manufacturer's instructions.

It's important to comply with relevant regulations and standards when using racking labels in order to ensure the safety of warehouse workers and to avoid penalties. Employers should seek professional advice and ensure their labelling system is compliant with the relevant legislation.