Floor Labels

Keep your warehouse organised and safe with our comprehensive selection of floor labels. Our labels are made of durable, weather-resistant materials and feature high visibility designs to ensure workers can find their way and stay safe. From directional arrows and exit symbols to safety messages, we have everything you need to improve efficiency and reduce hazards in your warehouse.

Comply With Regulations and Keep Your Warehouse Safe

Get your warehouse organised and safe with our range of floor labels. From footprint signals to directional arrows and safety messages, our durable and easy-to-apply adhesives will help improve efficiency and reduce hazards. Make sure your workers can find their way with clear exit symbols and fire exit markers. Trust our high-quality floor tape to withstand heavy foot traffic and industrial equipment. Don't let disorganisation and confusion slow you down - upgrade your warehouse today with our comprehensive selection of floor labels.

What Are Warehouse Floor Labels?

Warehouse floor labels are adhesive stickers that can be placed on the floor of a warehouse to help improve safety and efficiency. They can be used for a variety of purposes such as providing direction, identifying hazards, marking exits, and displaying safety messages. Examples of warehouse floor labels include footprint floor signals, directional arrows, floor tape, exit symbols, fire exit symbols, directional markers, and safety messages. These labels are typically made of durable materials that can withstand heavy foot traffic and industrial equipment.

What Are Some Common Uses for Warehouse Floor Labels?

Some common uses for warehouse floor labels include:

- Providing direction: Floor labels such as directional arrows and markers can be used to help guide workers through the warehouse and make it easier for them to find what they need.

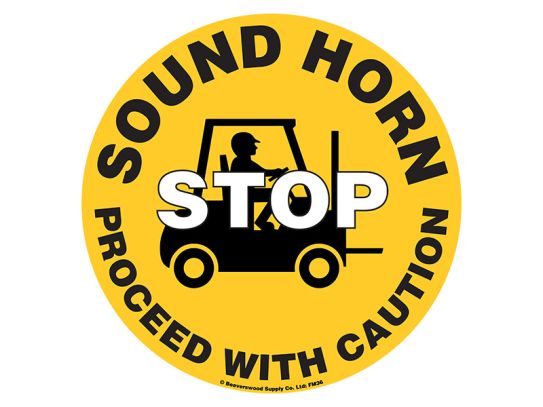

- Identifying hazards: Labels can be used to mark areas of the warehouse that are hazardous, such as wet floors or areas with heavy machinery.

- Marking exits: Exit symbols and fire exit markers can be used to help workers quickly locate exits in case of an emergency.

- Displaying safety messages: Safety messages can be used to remind workers of proper safety protocols and to encourage them to be aware of their surroundings.

- Creating walkways: Footprint floor signals and floor tape can be used to create designated walkways to help prevent congestion and improve traffic flow.

- Creating work areas: Floor labels can be used to create designated work areas, such as packing areas or loading docks.

- Marking inventory: Floor labels can be used to mark inventory locations, making it easy for workers to find what they need.

What Are the Different Types of Warehouse Floor Labels?

There are several different types of warehouse floor labels that can be used to improve safety and efficiency in a warehouse. Some common types include:

- Footprint floor signals: These labels are shaped like footprints and can be used to create designated walkways and help guide workers through the warehouse.

- Directional arrows: These labels are used to indicate the direction that workers should be going, they are commonly used to help guide traffic flow and to mark exits.

- Floor tape: This type of label is typically made of durable, non-slip material and can be used to create walkways, mark off areas of the warehouse, or indicate hazards.

- Exit symbols: These labels are used to indicate exits and help workers quickly locate them in case of an emergency.

- Fire exit symbols: Similar to Exit symbols, but specifically designed for emergency exit.

- Directional markers: These labels are used to mark specific areas of the warehouse and to indicate the direction that workers should be going.

- Safety messages: These labels are used to remind workers of proper safety protocols and to encourage them to be aware of their surroundings.

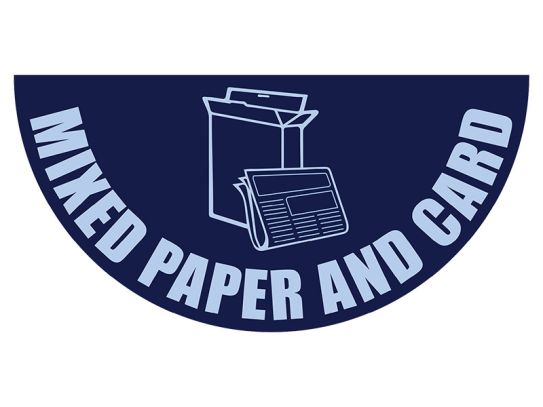

- Inventory labels: These labels are used to mark inventory locations, making it easy for workers to find what they need.

- Custom labels: These labels can be customised with your own text or logo, and can be used to indicate anything from restricted areas to designated parking spots.

What Are the Key Features to Consider When Choosing Warehouse Floor Labels?

When choosing warehouse floor labels, there are several key features to consider in order to ensure that they are effective and durable:

- Durability: The labels should be made of a durable material that can withstand heavy foot traffic and industrial equipment.

- Adhesion: The labels should have a strong adhesive that will keep them in place on the warehouse floor, even in high-traffic areas.

- Visibility: The labels should be highly visible and easy to read, even from a distance, to ensure that they are effective in guiding workers and identifying hazards.

- Reflectivity: Some labels come with reflectivity, which is useful in low light conditions and improves safety.

- Customisation: The labels should be customisable to meet the specific needs of your warehouse.

- Size and shape: The labels should be available in a variety of sizes and shapes, making them suitable for different areas of the warehouse.

- Weather resistance: The labels should be resistant to moisture, chemicals, and other environmental factors to ensure they last a long time.

- Compliance: It's important to ensure that the labels comply with OSHA and other safety regulations for your industry.

By considering these key features, you can ensure that you choose warehouse floor labels that are effective, durable, and well-suited to your specific needs.

How Do I Apply the Labels to the Warehouse Floor?

Applying warehouse floor labels to the floor is typically a straightforward process, but the specific method will depend on the type of label and the surface of the floor. Here are some general steps for applying warehouse floor labels:

- Clean the surface: Before applying the labels, make sure the surface of the floor is clean and free of debris. This will help ensure that the labels adhere properly and last as long as possible.

- Prepare the labels: Before applying the labels, make sure they are properly aligned and that any necessary cuts have been made.

- Apply the labels: Peel the backing off the label and apply it to the floor, making sure that it is properly aligned and that there are no bubbles or wrinkles in the label.

- Press the label down: Once the label is in place, press down firmly to ensure that the adhesive makes a good bond with the floor.

- Check for air bubbles: If there are any air bubbles under the label, use a tool like a squeegee or a credit card to push them out.

- Allow the labels to dry: If necessary, allow the labels to dry for a certain amount of time before using the area.

- Repeat the process: Repeat these steps for each label you need to apply.

It's important to make sure you have read the manufacturer instructions and follow them accordingly, some labels have specific instructions or require special tools or conditions to be applied.

Are There Any UK or European Industry Regulations That Apply to Warehouse Floor Labels?

In the United Kingdom, the Health and Safety Executive (HSE) sets regulations and guidelines for workplace safety, including safety in warehouses. These regulations include requirements for proper signage and labelling to help ensure the safety of workers.

- The EU regulations for workplace safety also apply in the UK, The EU Directive on the minimum health and safety requirements regarding the indication of the exit route, emergency lighting and fire-fighting equipment in the workplace.

- In addition, the EU Regulation on the provision of safety signs at work, which sets out the requirements for safety signs in the workplace, including the use of colour, design, and pictograms.

- It's important to ensure that any warehouse floor labels you use comply with these regulations and guidelines, and that they are highly visible and easy to understand. This includes using the right colours, symbols, and text to convey the necessary information clearly and effectively.

It is also important to note that some industries may have additional regulations that you need to follow, it is always recommended to consult with an expert or a professional to ensure that you are compliant with all regulations that apply to your industry.