Safety Steps

Helping You Reach New Heights in Warehouse Safety

Introducing our range of safety steps, made of sturdy steel, each ladder is designed with your safety and convenience in mind. With a range of styles to choose from, you can find the perfect ladder for your needs. Our cupped feet steps feature suction cups that lock the ladder in place when you step on them, while our lift and push steps can be easily moved around with handle bars, just like a wheel barrow.

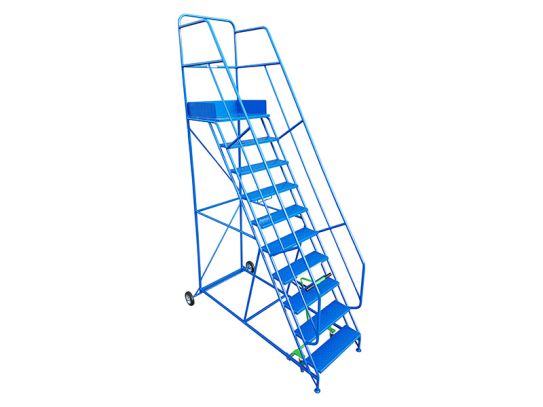

For even more convenience, check out our mobile safety steps, available in sizes from 5 to 15 treads. These ladders are perfect for use with warehouse racking, and feature a locking handle to keep them securely in place. And if you need to move your ladder through doorways, our knockdown steps are the perfect solution – they collapse down for easy transport.

Regardless of which style you choose, you can trust that our ladders are built to last. With non-slip treads, sturdy safety handrails, and a durable blue powder coat paint finish, our ladders are ready to handle any job.

What Are Safety Steps?

Safety steps are ladders specifically designed for use in warehouses. They are made of steel, which is a strong and durable material that can withstand the demands of warehouse use. These ladders feature non-slip treads, sturdy safety handrails, and a durable paint finish to help prevent corrosion and make them easy to clean. They have additional features, such as cupped feet or wheels, to help improve their stability and make them easier to move around the warehouse. Safety step ladders are an important tool for workers in warehouses, helping them to safely reach high shelves or perform other tasks that require them to work at height.

What Are Some Common Uses for Safety Steps?

Safety step ladders are commonly used for a variety of tasks in warehouses, including:

- Reaching high shelves to store or retrieve items.

- Performing maintenance or repair work on warehouse equipment or infrastructure.

- Loading and unloading items from trucks or other vehicles.

- Conducting inspections of warehouse equipment or structures.

- Assisting with the installation or removal of warehouse racking.

Safety steps are an essential tool for any worker who needs to perform tasks at height in a warehouse setting. They provide a safe and stable platform for workers to stand on, helping to prevent falls and other accidents.

What Are the Different Types of Safety Steps?

There are several different types of safety steps, each designed for specific uses and environments. Some common types of safety step ladders include:

- Cupped feet steps: These ladders feature suction cups on the feet that lock the ladder in place when you step on them, providing extra stability and preventing slips and falls.

- Lift and push steps: These ladders can be easily moved around using handlebars, just like a wheel barrow. They are a convenient option for workers who need to move their ladder from place to place.

- Mobile safety steps: These ladders are designed for use with warehouse racking, and feature a locking handle to keep them securely in place. They are available in a range of sizes, from 5 to 15 treads.

- Knockdown steps: These ladders are similar to mobile safety steps, but they can be collapsed down for easy transport through doorways and other tight spaces.

- Access platforms: These ladders have a large platform on top, in addition to 2-8 steps, making them ideal for maintenance work or loading and unloading tasks.

What Are the Key Features to Consider When Choosing Safety Steps?

When choosing safety steps, there are several key features to consider, including:

- Size: The size of the ladder should be appropriate for the tasks you need to perform, and the space you have available in your warehouse. Larger ladders with more treads may be more stable and comfortable to use, but they may also be more difficult to move around or store.

- Weight capacity: Make sure the ladder you choose is rated to support the weight of the heaviest person who will be using it. Overloading a ladder can cause it to tip or collapse, which can be dangerous.

- Stability: The ladder should be stable and secure when in use, to prevent slips and falls. Consider ladders with cupped feet or other stability-enhancing features, and make sure the ladder is properly set up and positioned before climbing.

- Ease of use: The ladder should be easy to move, set up, and use, to help make your job easier and more efficient. Consider ladders with wheels or other convenient features, and make sure the ladder is easy to climb and has comfortable handrails and treads.

- Durability: The ladder should be made of strong and durable materials, and should be able to withstand the demands of warehouse use. Look for ladders with a powder-coated finish or other corrosion-resistant features, to help them last longer and remain in good condition.

How Do I Choose the Right Size Safety Steps for My Needs?

When choosing the right size ladder for your needs, consider the tasks you will be performing with the ladder, as well as the space available in your warehouse. Larger ladders with more treads may be more stable and comfortable to use, but they may also be more difficult to move around or store in your warehouse. On the other hand, smaller ladders may be more convenient to move and store, but they may not be as stable or comfortable to use for extended periods of time.

To help you choose the right size ladder, consider the following factors:

- The height of the shelves or other objects you will be accessing with the ladder. You will need a ladder with enough treads to reach the desired height, without overextending yourself or the ladder.

- The width of the aisles or other spaces in your warehouse where the ladder will be used. Make sure the ladder will fit through doorways and other tight spaces, and that it will not block access to other areas of the warehouse.

- The maximum weight capacity of the ladder. Make sure the ladder is rated to support the weight of the heaviest person who will be using it, to avoid overloading and the risk of accidents.

- The availability of storage space for the ladder. Larger ladders may be more difficult to store, so consider the available space when choosing a ladder size.

The right size ladder for your needs will depend on your specific tasks and environment. It may be helpful to try out different sizes of ladders to see which one feels the most stable and comfortable to use.

Are There Any Safety Precautions I Should Take When Using Safety Steps?

Yes, there are several safety precautions you should take when using a steel warehouse safety step ladder. These precautions can help prevent accidents and injuries, and ensure that you use your ladder safely and effectively. Some common safety precautions to take when using a steel warehouse safety step ladder include:

- Make sure the ladder is properly set up and positioned before climbing. The ladder should be on level, stable ground, and should be set up at the proper angle to provide maximum stability.

- Always face the ladder when climbing or descending, and use the handrails for support. Do not try to carry items up or down the ladder, as this can cause you to lose your balance and fall.

- Do not climb higher than the highest safe standing level on the ladder. Overreaching can cause you to lose your balance and fall, so make sure you are able to comfortably reach the desired height without overextending yourself.

- Inspect the ladder before each use, and do not use it if it is damaged or unstable. Look for bent or damaged parts, loose or missing hardware, or other signs of wear or damage.

- Wear appropriate clothing and footwear when using the ladder. Avoid loose or baggy clothing that could catch on the ladder, and wear shoes with non-slip soles to help prevent slips and falls.

By following these safety precautions, you can help ensure that you use your safety step ladder safely and effectively. Remember to always use common sense and good judgement when working at height, and to seek help if you are unsure how to use your ladder properly.

How Do I Maintain and Care for My Safety Steps?

Proper maintenance and care can help to extend the life of your safety step ladder, and keep it in good working condition. Some common maintenance and care tips for safety steps include:

- Clean the ladder regularly, using a mild soap and water solution. Wipe the ladder down with a soft cloth or sponge, and make sure to clean any areas that are especially dirty or greasy.

- Inspect the ladder before each use, and do not use it if it is damaged or unstable. Look for bent or damaged parts, loose or missing hardware, or other signs of wear or damage.

- Store the ladder in a dry, well-ventilated area, away from extreme temperatures and direct sunlight. Avoid storing the ladder near heat sources, as this can cause the ladder to warp or become damaged.

- Avoid using the ladder for purposes other than those it was designed for. Do not use the ladder as a substitute for a scaffold, for example, as this can cause the ladder to become unstable and dangerous.

- Use the ladder according to the manufacturer's instructions, and do not exceed the maximum weight capacity of the ladder. Overloading the ladder can cause it to tip or collapse, which can be dangerous.

By following these maintenance and care tips, you can help keep your safety step ladder in good working condition, and extend its life. Remember to always use your ladder safely and properly, and to seek help if you are unsure how to maintain or care for it.

Are There Any UK or European Industry Standards or Regulations That Apply to Safety Steps?

Yes, there are several industry standards and regulations that apply to safety steps in the UK and Europe. These standards and regulations help to ensure that ladders are safe and fit for purpose, and provide guidelines for manufacturers, users, and other stakeholders.

- EN 131: This European standard sets out the requirements for portable ladders, including their design, construction, testing, and marking. It applies to all types of ladders, including safety steps.

- BS EN 14183: This British standard specifies the requirements and test methods for mobile access and working towers, including ladders and other access platforms. It applies to safety steps that are designed to be used as mobile access platforms.

- Work at Height Regulations 2005: These regulations, which apply in the UK, set out the requirements for working safely at height, including the use of ladders and other access equipment. They require employers to provide safe access equipment and training to workers who need to work at height, and to take steps to prevent falls and other accidents.

By complying with these standards and regulations, manufacturers, users, and other stakeholders can help to ensure that safety steps are safe and fit for purpose. It is important to familiarise yourself with these standards and regulations, and to follow them when using, maintaining, or caring for your ladder.